What’s Next

We are not stopping at blog posts. This publication directly supports our training efforts. From 23 to 27 June 2025, we are running a public, hands-on training course: Electronics and PCB Reverse Engineering. The course teaches exactly the kind of skills discussed in the article. It covers safe teardown and circuit tracing, component reidentification, overcoming challenging connectivity and debugging access when it all goes wrong, how chip to chip communication protocols actually work and how logic analysers can help.

This is not just another theory-heavy slide deck. Participants will spend time on the bench with real gear, real boards, and real problems. We are keeping it practical, intense, and focused on what actually happens in red team hardware engagements.

We have also been able to modify our course structure a little following some feedback – we now offer the ability to attend the first two days, the Deep Dive last three days, or all five days for the full course.

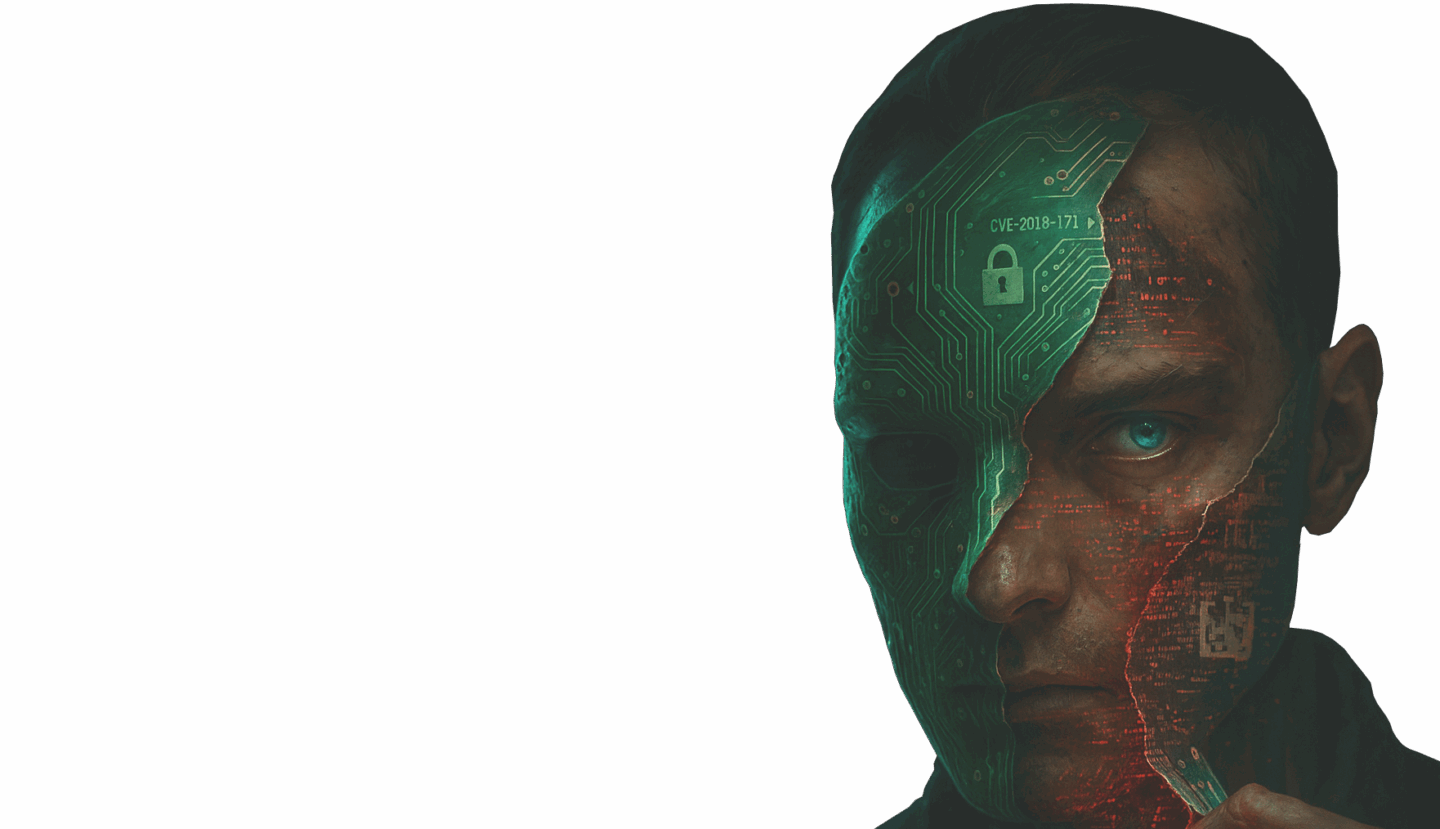

Come get your hands dirty. See what lies beneath the mask.